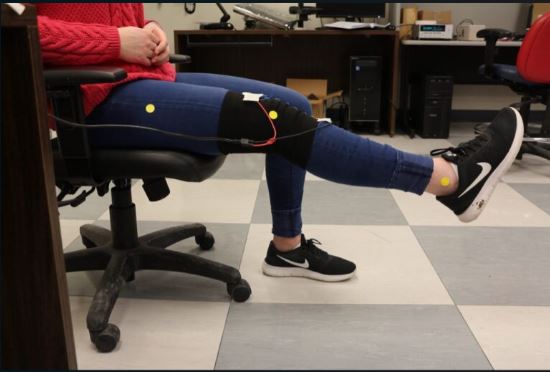

Present day smart materials that can be additively manufactured are limited to a few operational cycles and exhibit low strength and stiffness, hence restricting their standalone use in critical applications. This challenge can be addressed by merging the AM of active functional elements during the fabrication of intelligent structures. The research at Laboratory for intelligent structures focuses on improving the performance of 3D printed smart materials, increasing their compatibility with host structural materials, and creating highly reliable mechanical structures of the future.

Intelligent structures, those that adapt to changes in their surroundings are essential in creating reconfigurable, adaptive, and responsive structures. Additive manufacturing (AM) can play a crucial role in embedding novel sensing and actuation functionalities by adding smart materials into structural components, thereby creating lightweight intelligent structures.

Here, we work towards sustainable solutions and greener adaptive smart composites – during fabrication, service, as well as application stages of their lives. For example, creating lightweight, complex-shaped, aerodynamically efficient adaptive control surfaces for aircraft or lightweight conformal smart prosthetic components. With our research we aim to solve two current pressing problems in the manufacture of composite structures: 1. the decrease in mechanical properties upon addition of smart materials into composites 2. the large amount of material wastage during fabrication of complex shaped parts through conventional techniques.